Hazardous areas exist not only in mining and petrochemical industries but in a variety of industries including sewerage treatment plants, processing plants, manufacturing plants, chemical handling and storage plants/facilities and various others. Whilst the design, construction and maintenance processes of industrial plants are aimed to minimise the risk associated with hazardous areas, it is essential to ensure vigilance at all times.

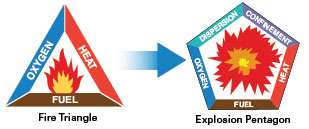

Generally, it is the presence and combination of three main elements that will lead to an explosion in a hazardous area:

- Fuel – explosive materials;

- Oxygen – either pure or in the air;

- A source of ignition ie. open flame, sparks etc.

The use of incorrect electrical equipment in hazardous areas can cause serious issues leading to extremely dangerous and potentially life threatening situations. Electrical equipment for use in hazardous areas is designed essentially around the objective of preventing the three elements from coming together. With the use of electrical equipment specifically designed for hazardous areas, and the installation and maintenance by qualified EEHA trained electricians, the equipment cannot, when used correctly, become a source of ignition, thereby creating a safer working environment.

To ensure the safety of plant, equipment and personnel, Australian Standards require that accredited & qualified electrical contractors are engaged to carry out any electrical works in hazardous areas.

At RJB Electrical Engineering Pty Limited, our staff have received EEHA accreditation with highly competent and nationally recognised training organisations. As such we are able to ensure that all hazardous area installations and maintenance meet with Australian Standards and relevant regulations.